What is the key role of waterproof technology in protecting internal circuitry and improving acoustic performance in bone conduction Bluetooth headsets?

Release Time : 2026-01-14

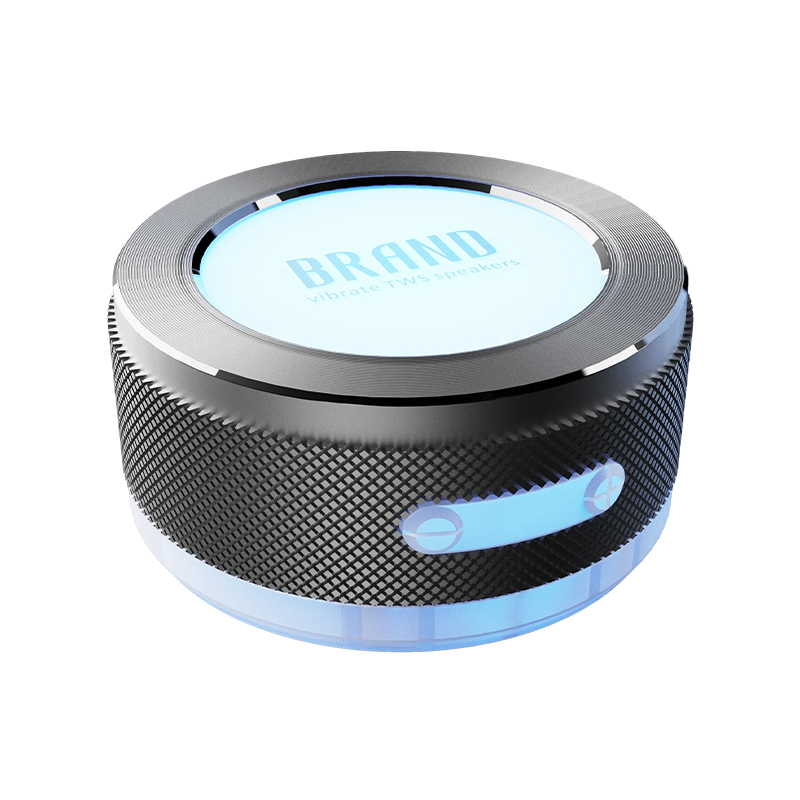

Bone conduction Bluetooth headsets, with their unique sound wave conduction method and open-back design, are increasingly becoming a popular choice for sports and daily commutes. Their waterproofing is not only a fundamental guarantee against daily damage from sweat and rain, but also a core factor determining the stability of internal circuitry and the durability of acoustic performance. From material selection to structural design, every detail of the waterproofing process directly affects the headset's durability and sound quality.

Internal circuit protection is the primary task of waterproofing. The core components of bone conduction headphones include the Bluetooth chip, battery, vibrator, and circuit board, all of which are extremely sensitive to humidity. If the waterproof rating is insufficient, sweat or rainwater can seep into the interior through the charging port, button gaps, or shell seams, leading to short circuits, component oxidation, or battery performance degradation. For example, headphones with an IPX7 waterproof rating can be briefly submerged in 1 meter of water, while an IPX8 rating supports underwater use such as swimming. High-end models use ultrasonic welding technology to seamlessly seal the shell, combined with a nano-level waterproof coating, forming a double barrier to ensure that the internal circuitry remains dry and stable even in high-humidity environments.

The impact of waterproofing on acoustic performance is reflected in the protection of the vibrating unit. Bone conduction headphones rely on a vibrating unit to drive the skull and transmit sound waves. If the vibrating unit corrodes or deforms due to water ingress, it will directly cause sound distortion, increased sound leakage, or decreased vibration efficiency. For example, some models use a hydrophobic membrane design around the vibrating unit, which can prevent water molecules from entering while allowing airflow to maintain the sensitivity of the vibration response. In addition, a closed acoustic cavity structure can reduce moisture residue, preventing diaphragm aging caused by long-term dampness, thereby extending the stable period of acoustic performance.

Matching the waterproof rating with the usage scenario is crucial in the design. For daily commutes or light exercise, IPX4 to IPX6 waterproof ratings are sufficient for sweat and rain protection; while swimming, diving, and other underwater activities require IPX8 waterproof support. For example, headphones supporting IPX8 typically use a magnetic charging interface to avoid the sealing failure caused by frequent plugging and unplugging of traditional jacks, and optimize the interface contact layout to ensure a balance between charging efficiency and waterproof performance. In addition, some models feature drainage channels at the charging port to quickly drain accidentally introduced moisture, further reducing the risk of damage to internal circuitry.

The synergistic optimization of waterproofing and wearing comfort is equally important. Bone conduction headphones need to transmit vibrations in close contact with the skull; if the shell is too thick or made of rigid materials due to waterproofing design, it will reduce comfort during extended wear. High-end models use lightweight titanium alloy frames and skin-friendly silicone coatings to improve waterproofing while reducing weight and ensuring a close fit to the skin. For example, some headphones use a nano-level hydrophobic coating on the surface where the vibrator contacts the skin, reducing sweat adhesion and avoiding weight increase due to water absorption, thus balancing waterproofing performance and wearing comfort.

Waterproofing plays a decisive role in extending the lifespan of headphones. The long-term stability of the internal circuitry and vibrator directly determines the headphone's lifespan. If the waterproofing is flawed, the headphones may experience performance degradation or even complete damage in a short period due to water ingress. Through rigorous waterproof testing and material selection, such as simulating extreme environments like prolonged exposure to sweat or high-pressure water jets, the headphones achieve higher reliability in real-world use. Some brands even offer "diving-grade" waterproof certification, further reinforcing user confidence in the product's durability.

Upgraded waterproofing technology has also driven the expansion of bone conduction headphones' functionality. For example, headphones supporting IPX8 waterproofing typically have built-in high-capacity batteries and independent storage chips, allowing them to be used as MP3 players independently of a mobile phone, meeting entertainment needs in scenarios without signal, such as swimming. Furthermore, improved waterproofing makes it possible to use headphones in extreme weather or high-humidity environments, such as running in the rain or surfing at the beach, thus broadening the product's application scenarios.

The waterproofing technology of bone conduction Bluetooth headsets is not only a basic protective function but also a comprehensive reflection of internal circuit stability, acoustic performance durability, wearing comfort, and product lifespan. From material selection to structural design, from waterproofing rating matching to functional expansion, every detail of the process undergoes rigorous testing and optimization to provide users with a truly reliable and durable listening experience.